A Brief Guide on Screen Printing Procedure

Screen printing is a popular process to transfer a stenciled design into a flat surface through ink, mesh screen, and squeegee. In general, the screen-printing process is followed for printing books or other kinds of stuff, but there are special techniques for printing on other surfaces like wood, glass, plastic, or metal.

The procedure is also known as silk printing and silk screen printing, and professionals use different stenciling tricks to complete the process.

Creation of Design

The first step of screen printing is designing. Professionals create a design on the finished product, and when it is done, they print the design on a transparent acetate film. The film will be used to make the stencil and this the first step of screen printing.

Preparation of Screen

Once the design is completed, it’s time to choose a mesh screen for printing it. Professionals apply light-reactive emulsion that is hardened when it exposed to light. This is the second step of screen printing, and this is how professionals do it. The screen should not be uneven at any place and only an experienced printer knows how to utilize this screen to get multicolored designs.

Layering

People have seen prints with multiple colors, and this is done through a special technique. The screens are used as a layer, and one needs to use multiple screens for applying multiple colors in screen printing. For garments, there is a specific layer used, for books, magazines, and for other paper or block prints, there is another use. Choosing the layer and the stencil, along with the mesh is very important.

Washing off Emulsion

The screen needs to be exposed under a bright light for a certain period before washing off the emulsion. Once the design has got hard, it’s time to rinse. The process is performed carefully so that the design remains intact, and it leaves a clear imprint upon the screen, and it will help the ink to pass through. It is important to choose the light reactive emulsions and then check the total time taken for printing and also to find out if there are any complications in the process of printing.

Preparing For Print

Once the previous steps are done, the screen is taken to the press for printing. The paper, garment, or item is placed on the printing board and the screen is placed on the top of it. Automatic rotary carousel printers allow inserting different screens and work together, whereas manual style printers don’t allow it. The product is dried and checked to find out if the ink has dried up.

In case professionals use commercial printers for screen printing, the process won’t be tough, but if people are using manual style printers, they have to be careful.

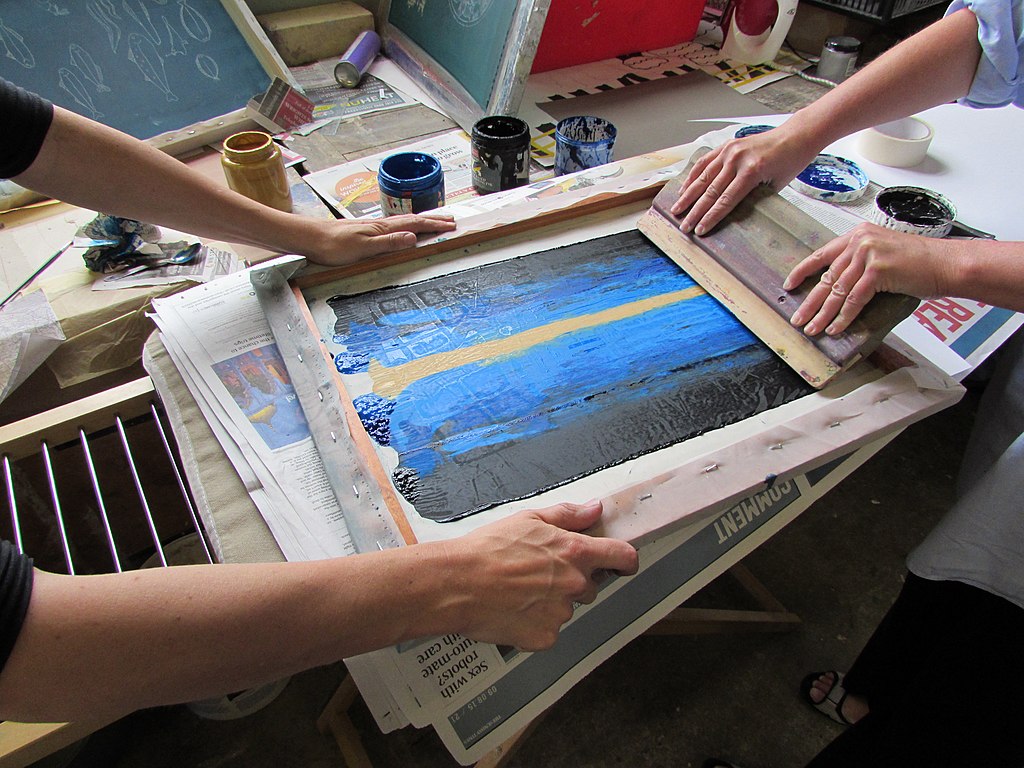

Using Ink

The screen is then placed on the printing board, and professionals put the ink on the top end of the surface. Then the squeegee is used to spread the ink throughout the screen. The ink passes through the open areas creating the desired design beneath the screen.

The process can be repeated if you are making multiple pieces, and once the printing process is done the work is almost completed. Professionals use special washing fluid for removing the hardened emulsion so that the mesh can be used again in the future.

The Final Step

Once the above-mentioned steps are done, it’s time to dry the item. Professionals use dryers for creating a smooth and colorfast finish, and sometimes they wash the final product in case of any residue.

We hope readers have got an idea about screen printing. You can also help others by sharing the article.

The post A Brief Guide on Screen Printing Procedure appeared first on Sunshine Slate.

source https://www.sunshineslate.com/living/fashion/a-brief-guide-on-screen-printing-procedure/

Comments

Post a Comment